Cardboard tubes and cardboard cores are a winding support whose technical performances controlled by Abzac are particularly suited to the paper-making industry.

Cardboard core crush and dynamic load resistance: this is the capacity of the cardboard tube to withstand the variations in speed and weight of the rolls during winding and unwinding.

The E-modulus: this value serves to determine the critical speed as from which the cardboard tube starts to vibrate and resonate.

Cardboard tubes resistant to the constraints of radial compression or surface defects (waviness or roughness).

As a result of its R&D, Abzac has developed a range of cardboard tubes capable of meeting the specific constraints of plastic films:

Radial cardboard tubes: radial pressure is a specific problem in the winding of certain films. Abzac is capable of controlling this radial pressure, thus increasing the reliability of the cardboard tube and enabling further enhancement of the tube’s specifications.

Smooth cardboard tubes: Abzac offers a range of smooth cardboard tubes with full control of the surface appearance to minimise marking of the film by the cardboard tube.

Thanks to specific tooling, the cardboard tubes and rings are cut to length with remarkable precision. Particular care and attention is paid to packaging of cardboard tubes.

Cardboard tubes and rings can be marked or printed on the inside.

Abzac has extensive expertise in this field, particularly for the wound metal market.

The shells serve as a winding support with strong crush resistance to withstand the weight during metal winding, which varies according to the winding tension.

The shells can be used as a protective sleeve to protect wound metal: they can be very thin and delivered folded.

With more than half a century of experience in manufacturing cardboard tubes, Abzac offers a wide range of cardboard formwork tubes for concrete, which are strong, practical, and lightweight:

The "standard" concrete tube, the "regular" concrete tube, which allows a smooth and uniform finish, the "super" concrete tube for structural construction, "joint-free" concrete tubes for formwork of concrete columns without a visible spiral joint.

For packaging of adhesives, silicones and mastics, different sizes (300 ml, 500 ml), with an applicator tip. These caulking cartridges can be customised.

Abzac offers a wide range of cardboard tubes, reliable and adapted to main user markets: paper industry, the plastic film industry, for labels and adhesives, textiles and non-woven materials, printing tubes. Sending tubes with end caps, cardboard tubes for cables, strips, surface protection, storage tubes...

| References | Ø Inside | Thickness | Lenght | Features | Applications |

|---|---|---|---|---|---|

| AZ Spiral cardboard tubes |

25 to 1000 mm | 1 to 20 mm depending on Ø |

5 mm to 10 m | Strenght, tolerance, straightness depending on specifications | Winding of paper, board and plastic films |

| AZ HR High resistance cardboard Tubes |

Specific models Consult us for the different dimensions | Crush, dynamic load and vibration (E-modulus) resistance | Very high speed winding, unwinding and printing of heavyweight rolls | ||

| AZ S Improved surface cardboard Tubes |

Smooth surface, controlled waviness and roughness | Winding of thin films or papers | |||

| AZ RC Radial compression cardboard Tubes |

Control of tube contraction (squeeze effect and ovalisation) | Stretch plastic films | |||

| AC Convolute cardboard Tubes |

28 to 80 mm and 225 to 600 mm |

2 to 10 mm depending on Ø and 3 to 30 mm |

Up to 2050 mm |

Straight, flexion resistance winding | Textiles, dyes and primers metal sheets |

The cardboard tube is a technological product which requires know-how, precision, regularity and cleanliness.

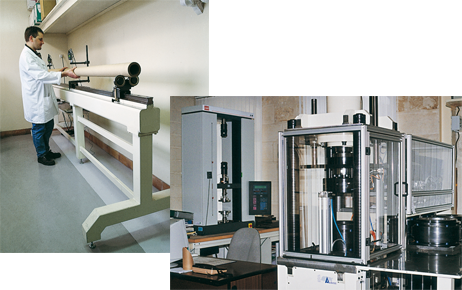

Abzac has been specialised in the production of cardboard tubes for over 80 years. Thanks to the investments made in its central laboratory, it continues to innovate in order to offer ranges of high performance cardboard tubes. Abzac fully masters performances such as :

As part of its constant quality policy, Abzac meets the requirements of the ISO 9001-V 2015 standard.

Thanks to its know-how and in-depth knowledge of cardboard, Abzac can meet the requirements of cardboard tube and cardboard core markets and users.

Several years of research have made it possible to determine the technical characteristics of a specific cardboard for cardboard tubes.

In cooperation with its partner suppliers, Abzac has developed a raw material which meets the constraints to which the cardboard tubes are subjected.

Control of the raw material together with the measurement capacity guarantees the result.

Abzac today offers a range of standard, versatile and customizable cardboard tubes.

Cookies allow us to personalise content and ads, provide social social media-related features and analyse our traffic. We also share information on the use of our website with our partners, who may combine this with other information you have provided or they have collected when you used their services. Learn more