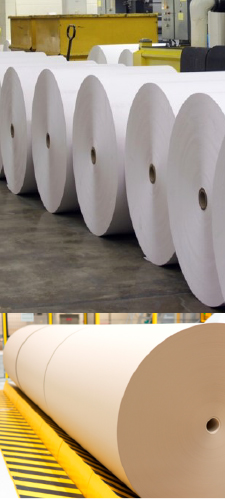

The tube serves as a support for the winding and unwinding of paper. The manufacturing process of paper tubes and cores enables high-speed winding, unwinding and printing of heavy paper rolls.

Abzac’s technical approach has led to the development of a range of cardboard tubes designed to meet the specific requirements of the paper-making markets:

Abzac has its own research laboratory for the analysis, adjustment and control of all these parameters.

The manufacturing process allows the control and reproducibility of the geometric criteria (straightness, roundness) and of the resistance performance levels.

Customer advantages

| 3” - Ø 76 th15 | Un | HR A3 | HR A4 | HR A5 | HR A7 |

|---|---|---|---|---|---|

| Ø-int | mm | 3"-76 mm | 3"-76 mm | 3"-76 mm | 3"-76 mm |

| Ø-ext | mm | 4,19"-106,5 mm | 4,19"-106,5 mm | 4,19"-106,5 mm | 4,19"-106,5 mm |

| Max. deflexion | mm/ml | 2 | 2 | 2 | 2 |

| E-modulus | N/mm2 | 2500 | 2800 | 3200 | 4000 |

| Dynamic load-DaN/ml | DaN/ml | 1000 | 1200 | 1500 | 2000 |

| Crush resistance | N/100mm | 3000 | 3500 | 4500 | 5500 |

| Weight | Kg/ml | 3 | 3.2 | 3.7 | 4.15 |

| Humidity | % H2O | 8 | 8 | 8 | 8 |

Cookies allow us to personalise content and ads, provide social social media-related features and analyse our traffic. We also share information on the use of our website with our partners, who may combine this with other information you have provided or they have collected when you used their services. Learn more